Paper pulp packaging is becoming a Main emphasis for firms globally as they change far from unsustainable supplies toward eco-friendly alternatives. Molded pulp packaging provides a sustainable and value-successful way to produce substantial-excellent packaging which is customizable and biodegradable. One area driving innovation will be the introduction of significant-effectiveness pulp molding equipment, such as Dwellpac Semi-Hotpress Machine. These devices aid corporations eco friendly box packaging streamline creation even though making sure precision and dependability.This article will check out The real key attributes of substantial-performance pulp molding machines, servicing techniques for extensive-term usage, approaches to chop charges whilst maximizing output, and how automation boosts creation and high quality. irrespective of whether you might be a business operator or maybe a packaging Skilled, you can get important insights to help optimize your generation course of action.

Table of contents:

critical functions of High-effectiveness Pulp Molding Machines

routine maintenance techniques for lengthy-time period equipment Performance

Value-conserving approaches in output

How Automation enhances Output and excellent

important Features of High-performance Pulp Molding devices

substantial-effectiveness pulp molding equipment are revolutionizing how molded pulp suppliers operate. The Dwellpac Semi-Hotpress device is one particular these kinds of example. It stands out for its Sophisticated Command method, large clamping accuracy, and seamless hydraulic functionality. With capabilities like precision shaping and eco-helpful mold urgent technological innovation, it makes certain that each eco-helpful box packaging products is consistent in quality and sturdiness. This is important for industries needing tailor-made solutions like food items packaging, electronics, and industrial components. this sort of machines also assistance A variety of customized molded pulp packaging desires, giving substantial flexibility in manufacturing.

upkeep methods for very long-expression device efficiency

sustaining a pulp molding device is critical to making sure constant output and maximizing its lifespan. Regular maintenance jobs incorporate cleaning the molding surfaces, inspecting hydraulic methods for wear and tear, and making certain the Handle procedure is current for peak overall performance. The Dwellpac equipment is meant to simplify these procedures, allowing for molded pulp makers to streamline upkeep. normal inspections and proactive treatment not simply lessen unanticipated breakdowns but also assist keep the precision standards necessary for large-quality paper pulp packaging.

Charge-Saving Strategies in output

Value-usefulness is a primary issue for molded pulp companies. to save lots of prices whilst maintaining quality, they're able to optimize content use by leveraging effective pulp mold pressing technological innovation to attenuate squander, spend money on Electricity-successful equipment much like the Dwellpac Semi-Hotpress Machine to lessen Strength consumption, and prepare staff to totally make the most of Superior equipment to prevent faults that produce inconsistencies or wastage. Also, ordering eco-friendly products in bulk might help take full advantage of reduced selling prices and decrease All round production expenses. By adopting these approaches, brands can remain aggressive although providing high-good quality, personalized eco-helpful packaging to clientele.

How Automation enhances Output and high quality

Automation happens to be a pivotal element of recent output processes. Superior pulp molding device brands, which include Dwellpac, combine automation to improve operational efficiency. Automated methods, by which includes characteristics like intuitive Regulate panels and authentic-time precision checking, reduce the probability of human problems. This ensures that each individual mildew generated meets rigid quality specifications. With automation, organizations might also deal with big-scale output runs a lot more efficiently, meeting specific deadlines although creating molded fiber packaging at competitive fees. Furthermore, the steady top quality obtained by automation reinforces consumer rely on in eco-pleasant packaging remedies.

High-efficiency pulp molding equipment are enabling firms to fulfill raising need for sustainable packaging solutions. By purchasing advanced systems, providers can create personalized molded paper pulp products that not just shield the surroundings but additionally give top-quality efficiency and sturdiness. With ground breaking devices and thoughtful routine maintenance tactics, organizations can triumph over creation worries, reduce operational costs, and supply eco-pleasant products which cater to global sustainability targets.

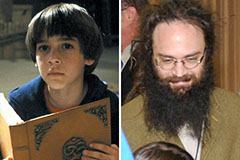

Barret Oliver Then & Now!

Barret Oliver Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Shane West Then & Now!

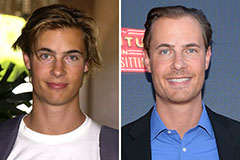

Shane West Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now!